Dielectric Testing Tulsa

In a world driven by technology and powered by electricity, ensuring the safety and reliability of our electrical systems is more critical than ever. Picture a landscape where every flicker of light, every hum of machinery, and every pulse of power flows effortlessly without interruption. This vision can become a reality for businesses in Tulsa, Oklahoma, through comprehensive dielectric testing.

Electrical systems are the unseen backbone of our industries, supporting everything from complex industrial machinery to essential residential functions. As we innovate and strive for greater efficiency, the importance of maintaining these systems only escalates.

A single electrical failure can lead to significant operational disruptions, safety risks, and substantial financial losses. In these moments of high demand and heightened risk, Dielectric Testing Services Tulsa, Oklahoma, emerges as a vital partner. It’s not just a technical procedure; it’s a pledge to protect our progress, our people, and our future.

Understanding Dielectric Testing

At its core, dielectric testing involves applying a high voltage to a device or system to determine its insulation quality. This testing method is essential for identifying weaknesses in insulation that could lead to failures, electrical hazards, or costly downtime.

The test measures the material’s ability to withstand electrical stress without breaking down, providing vital data that can help prevent electrical failures before they occur.

What Are The Importance of Dielectric Testing Services

Here are the most necessary benefits of Dielectric Testing Services Tulsa, Oklahoma, that will make your operation secure and smooth:

Safety Compliance: Dielectric testing is essential for adhering to industry safety standards. It ensures that equipment meets regulatory requirements, safeguarding both employees and machinery from potential hazards.

Preventive Maintenance: Conducting regular dielectric testing is a key component of preventive maintenance. It allows for early detection of insulation deterioration, helping organizations avoid unexpected outages and high repair costs.

Operational Efficiency: By verifying that insulation is in peak condition, dielectric testing enhances the efficiency of electrical systems. This can result in improved performance and reduced energy expenses, contributing to overall operational effectiveness.

Asset Protection: Dielectric testing plays a crucial role in protecting valuable electrical assets. It significantly reduces the likelihood of catastrophic failures, which can lead to costly replacements and prolonged downtime.

Risk Management: Implementing dielectric testing services helps organizations proactively manage risks associated with electrical failures. This not only mitigates financial losses but also fosters a safer working environment.

Increased Reliability: Regular dielectric testing ensures that electrical systems function reliably over time. This reliability not only supports business continuity but also builds trust with clients and stakeholders.

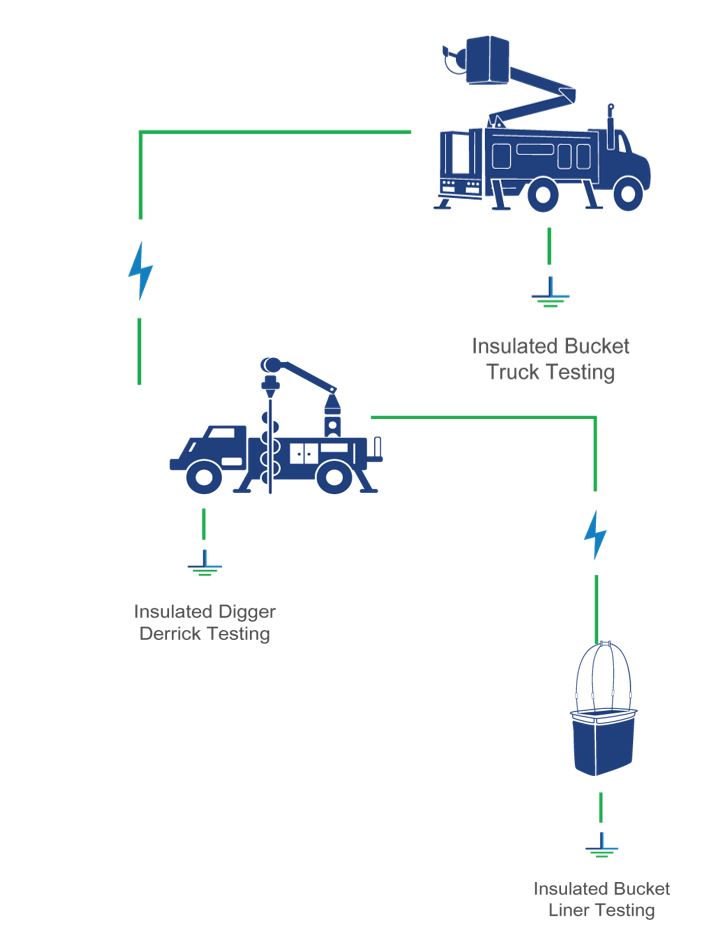

What Are KEMPCO Inspection Services, Inc. Dielectric Testing Services?

Dielectric Testing Services Tulsa, Oklahoma offers a comprehensive range of dielectric testing services tailored to meet the unique needs of various industries, including manufacturing, energy, telecommunications, and more. Our state-of-the-art equipment and highly trained technicians ensure that each test is performed with precision and accuracy.

Insulation Resistance Testing: This test measures the resistance of the insulation to leakage currents, providing insights into the integrity of insulation materials. By comparing the resistance levels to industry standards, we can identify potential issues that need addressing.

Dielectric Withstand Testing (HiPot Testing): Dielectric withstand testing involves applying a high voltage to the insulation system to ensure it can handle the operational voltage without failure. This test is crucial for validating the design and manufacturing of electrical equipment.

Power Factor Testing: Power factor testing helps assess the condition of electrical insulation systems. By analyzing the power factor and dissipation factor, we can determine the insulation’s health and predict its remaining lifespan.

Transient Voltage Testing: Transient voltage testing evaluates the system’s ability to withstand sudden voltage spikes, which can occur due to switching actions or lightning strikes. This testing is vital for protecting sensitive equipment.

Routine Testing Services: We also provide routine dielectric testing as part of a comprehensive maintenance program. Regular testing helps to identify insulation degradation and ensures compliance with safety standards.

Why Choose KEMPCO Inspection Services, Inc. Dielectric Testing Service?

Choosing the right dielectric testing provider is crucial for safety in Lafayette’s complex electrical systems. Dielectric Testing Services Tulsa, Oklahoma ensures your insulation meets standards, protecting your operations and workforce across various industries.

Expertise and Experience: Our team comprises certified technicians with extensive experience in dielectric testing. We are committed to delivering accurate results and expert analysis to help you make informed decisions.

State-of-the-Art Equipment: We use the latest technology and equipment to perform dielectric testing, ensuring precise and reliable results. Our investment in advanced tools means you receive the best service available.

Customized Solutions: We understand that each business is unique. Our dielectric testing services are tailored to meet the specific needs of your operations, whether you require one-time testing or ongoing support.

Comprehensive Reporting: Following each testing session, we provide detailed reports outlining our findings and recommendations. This documentation helps you understand the condition of your insulation systems and make strategic maintenance decisions.

Commitment to Safety: Safety is our top priority. We adhere to all industry safety standards and protocols, ensuring that our testing processes protect your employees and assets.

The Dielectric Testing Process

Dielectric Testing Services Tulsa, Oklahoma is essential for assessing the insulation quality of electrical equipment, helping to identify weaknesses that could lead to failures. Our streamlined process includes several key steps:

Initial Consultation: Our process begins with a detailed consultation designed to understand your unique needs and objectives. During this discussion, our experts will explore the specific types of dielectric testing that are most suitable for your equipment and facilities. This collaborative approach ensures that we tailor our services to meet your operational requirements effectively.

Site Assessment: Prior to conducting any testing, we perform a comprehensive site assessment. This step is crucial, as it allows us to identify any specific considerations or challenges that may impact the testing process. By evaluating the environment and existing infrastructure, we can better prepare for a smooth and efficient testing operation.

Testing Execution: Our skilled technicians carry out the selected dielectric tests using state-of-the-art equipment. We adhere strictly to industry standards throughout this process, ensuring that all tests are executed with precision and care. Our team is committed to delivering accurate and reliable results, minimizing downtime for your operations.

Data Analysis: After the testing is complete, we thoroughly analyze the data collected. This analysis is critical for identifying any insulation weaknesses or potential risks that could compromise the safety and efficiency of your equipment. Our experts interpret the results with a keen eye, ensuring that no detail is overlooked.

Reporting and Recommendations: Finally, we provide you with a comprehensive report that details our findings in a clear and accessible manner. Alongside this, we offer actionable recommendations for maintenance or repairs that can help mitigate any identified risks. Our goal is to empower you with the information needed to enhance the reliability and longevity of your equipment.

Contact Our Team Today for Dielectric Testing Services in Tulsa, Oklahoma

At Dielectric Testing Services Tulsa, Oklahoma, our team of experienced professionals utilizes state-of-the-art equipment and techniques to deliver precise and reliable dielectric testing results. We recognize the critical role dielectric testing plays in maintaining the integrity of your electrical systems and are committed to providing exceptional service tailored to your specific needs.

Whether you need to schedule a testing appointment, have questions about our services, or seek expert advice on your electrical systems, we’re here to help. Contact KEMPCO Inspection Services, Inc. at (713) 926-1005 today and take the first step toward ensuring the safety and efficiency of your electrical operations.

We look forward to partnering with you to safeguard your electrical systems and create a reliable operational environment.

On-Site Testing Available: No Need to Drop Your Equipment Off At Our Shop

Our Trusted Partners

Kempco works with a variety of associations and councils to maintain the highest standards in our inspections. This gives you the trust you are looking for when searching for a qualified, experienced crane inspector.

![]()

Kempco Inspection Services, Inc.

4747 Gulf Freeway

Houston, TX 77023

Inspector Base Locations:

- Southern Texas,

- Oklahoma and

- Louisiana

Service Area

Nationwide